NJ5

Контроллер Sysmac – серия NJ5

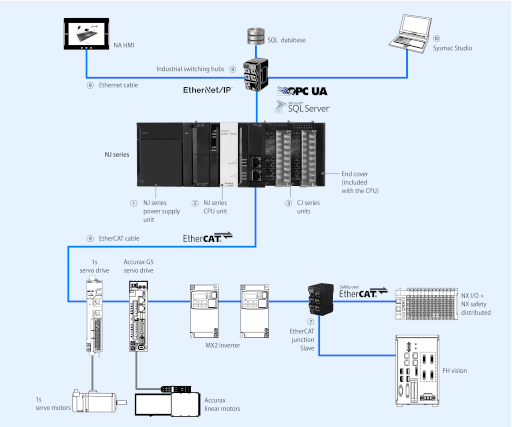

Контроллер серии NJ5 представляет собой универсальный машинный контроллер для программно-логического программирования и управления движением, который отличается расширенной функциональностью ЦПУ, такой как управление роботами и подключение к базам данных.

- Минимальное время цикла: 500 мкс

- Количество осей: 64, 32, 16

- Синхронизированное ядро управления движением

- Функции: программно-логическое программирование, управление движением, обработка G-кодов, управление роботами, подключение к базе данных, SECS/GEM

- Управление роботами Delta, SCARA и Cartesian

- Подключение к базе данных: клиент SQL для сервера Microsoft SQL, Oracle, IBM DB2, MySQL, Firebird

- Поддерживаемые функции ЧПУ идеально подходят для задач координатной резки, фрезерования, шлифования и любых других применений с заданной траекторией, например в дозирующих, гибочных, шлифовальных и формовочных установках

- Многозадачность

- Встроенные порты EtherCAT и EtherNet/IP

Ordering information

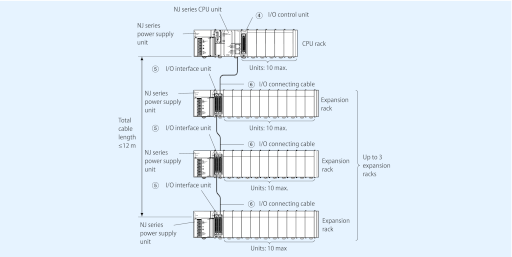

NJ series system

NJ series expansion racks

Power supply units

Note: Power supply units for the CJ Series cannot be used as a power supply for a CPU rack of the NJ System or as a power supply for an expansion rack.

NJ5 series CPU units

| NJ501-43101 | ||||||||||||

| 162 | NJ501-53003 | |||||||||||

Note: The end cover unit CJ1W-TER01 is included with the CPU unit.

CJ series digital I/O units

Note: MIL = Connector according to MIL-C-83503 (compatible with DIN 41651/IEC 60603-1).

CJ series analog I/O and control units

| Accuracy4 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Universal inputs, with zero/span adjustment, configurable alarms, scaling, sensor error detection | ||||||||||||

| Offset/gain adjustment, scaling, peak hold, moving average, alarms, output hold | ||||||||||||

| All inputs individually isolated, configurable alarms, maintenance functions, user-defined scaling, zero/span adjustment | ||||||||||||

| Configurable alarms, maintenance functions, user-defined scaling, zero/span adjustment, square root, totaliser | ||||||||||||

| Basic I/O unit, setup by DIP switches, adjustable filtering | ||||||||||||

| Basic I/O unit, setup by DIP switches, adjustable filtering | ||||||||||||

CJ series special I/O units

CJ series communication units

| CJ1W-EIP215 | |||||||||

| CJ1W-ECT216 | |||||||||

| CJ1W-CRM217 | |||||||||

| RS-232C to RS-422A/RS-485 signal converter. Mounts directly on serial port | |||||||||

CJ series ID sensor units

| 0.268 | 0.131 | |||||||

Note: The data transfer function using intelligent I/O commands can not be used.

Expansion racks

CJ series I/O control unit (mounted on CPU rack when connecting expansion racks)

Note: Mount to the right of the power supply unit.

I/O connecting cables

EtherCAT junction slave

- Note 1. Please do not connect EtherCAT junction slave with OMRON position control unit, Model CJ1W-NC_81/_82.

- 2. EtherCAT junction slave cannot be used for Ethernet/IP and Ethernet.

Industrial switching hubs

| Quality of Service (QoS): EtherNet/IP control data priority. Failure detection: Broadcast storm and LSI error detection 10/100 BASE-TX, Auto-Negotiation | ||||||

Recommended EtherCAT and EtherNet/IP communication cables

| Cable with connectors on both ends  | |||||||

| Cable with connectors on both ends  | |||||||

| Cable with connectors on both ends (RJ45/RJ45)  | |||||||

| Cable sheath material: PUR1 | Cable with connectors on both ends (RJ45/RJ45)  | ||||||

| Cable with connectors on both ends (RJ45/RJ45)  | |||||||

| Cable with connectors on both ends (M12 straight/RJ45)  | |||||||

| Cable with connectors on both ends (M12 L right angle/RJ45)  | |||||||

| Cat 5, SF/UTP, 4 × 2 × AWG 24/1 (solid core), Polyurethane (PUR) | |||||||

| Cat 5, SF/UTP, 4 × 2 × AWG 26/7 (stranded core), Polyurethane (PUR) | |||||||

| DIN-rail mount socket to terminate installation cable in the cabinet | |||||||

Note: Please be careful while cable processing, for EtherCAT, connectors on both ends should be shield connected and for EtherNet/IP, connectors on only one end should be shield connected.

WE70 FA wireless LAN units

| ||||

Note: Special versions are available for USA, Canada, China and Japan.

NJ series options and accessories

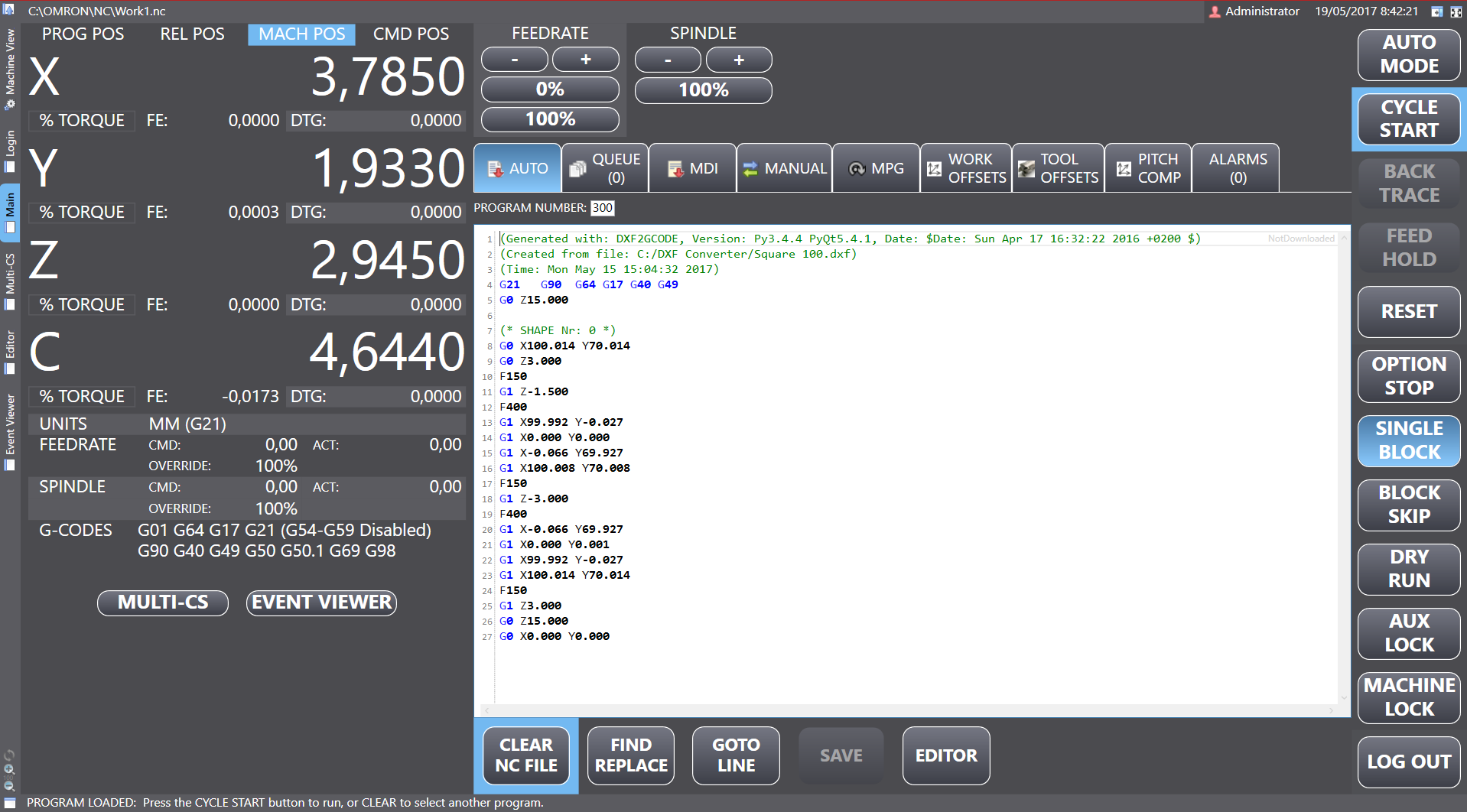

Computer software

| SYSMAC-SE2___13 | ||||

| Software that provides a operation interface for NC programming, debugging and maintenance of CNC machine | Download link: | |||

| License for the CNC Operator software (hardware key, USB dongle). The CNC Operator needs license key | ||||

4. Accuracy for voltage and current inputs/outputs as percentage of full scale and typical value at 25°C ambient temperature (consult the operation manual for details)

Accuracy for temperature inputs/outputs as percentage of process value and typical value at 25°C ambient temperature (consult the operation manual for details)

5. Supported only by the EtherNet/IP units with unit version 2.1 or later, CPU units with unit version 1.01 or later and the Sysmac Studio version 1.02 or higher.

6. Supported only by the CPU units with unit version 1.10 or higher and the Sysmac Studio version 1.13 or higher.

7. Supported only by the CPU units with unit version 1.01 or higher and the Sysmac Studio version 1.02 or higher.

9. The lineup features low smoke zero halogen cables for in-cabinet use and PUR cables for out-of-cabinet use.

4. Accuracy for voltage and current inputs/outputs as percentage of full scale and typical value at 25°C ambient temperature (consult the operation manual for details)

Accuracy for temperature inputs/outputs as percentage of process value and typical value at 25°C ambient temperature (consult the operation manual for details)

5. Supported only by the EtherNet/IP units with unit version 2.1 or later, CPU units with unit version 1.01 or later and the Sysmac Studio version 1.02 or higher.

6. Supported only by the CPU units with unit version 1.10 or higher and the Sysmac Studio version 1.13 or higher.

7. Supported only by the CPU units with unit version 1.01 or higher and the Sysmac Studio version 1.02 or higher.

9. The lineup features low smoke zero halogen cables for in-cabinet use and PUR cables for out-of-cabinet use.

Sysmac Studio — интегрированная среда разработки

- Один инструмент для программно-логического управления, управления движением, роботами, техническим зрением, человеко-машинным интерфейсом, а также обеспечения безопасности и связи с базой данных

- Открытый стандарт IEC 61131-3

- Библиотека Sysmac для оптимизации времени разработки и готовности оборудования

- Редактор файлов с G-кодом

- Исполнительный монитор для G- и M-кодов

- Терминал ввода команд

- Ручная подача, возврат в исходное положение

- Настраиваемое ПО позволяет разработчикам изменять интерфейс по запросу пользователей (требуется CNC Operator версии SDK)